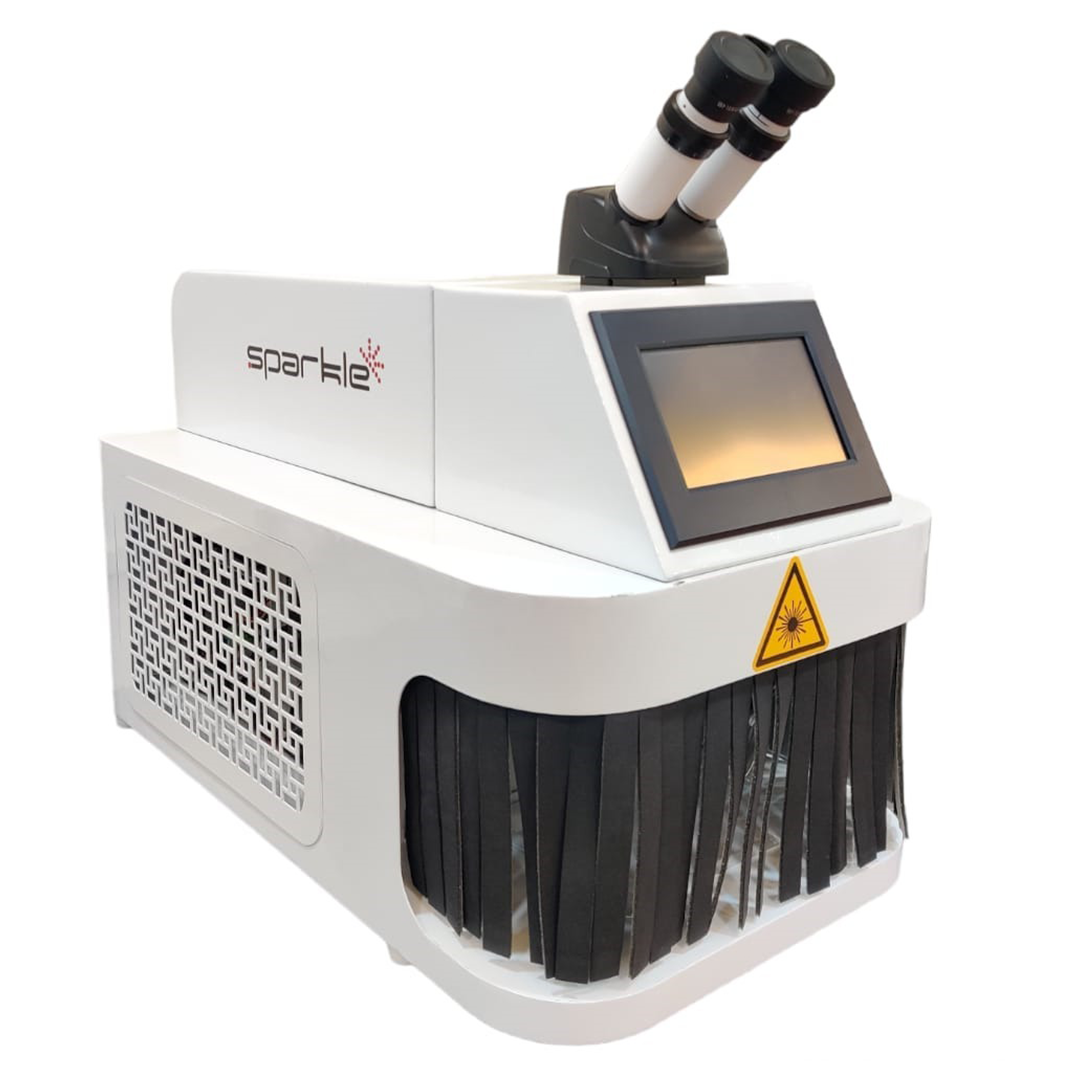

Nova Table Top Laser Soldering Machine

In the realm of precision soldering and welding, laser technology has taken center stage. Laser soldering machines have revolutionized the way intricate welding tasks are accomplished. Additionally, silver welding machines play a crucial role in creating durable and high-quality joints. In this guide, we'll delve into the world of laser soldering machine price and silver welding machines, exploring their features, benefits, and much more.

Laser Soldering Machine Price: Unveiling the Affordability

Laser soldering machines have become a staple in various industries due to their precision and efficiency. When considering laser soldering machine price, it's important to evaluate the features and capabilities that align with your specific needs. The price range for these machines can vary significantly based on factors such as power, wavelength, and additional functionalities. High-end models with advanced features may command a higher price, while more basic models can be budget-friendly.

Silver Welding Machine: Enhancing Durability and Strength

Silver welding machines are renowned for their ability to create robust joints that withstand the test of time. These machines utilize silver-based filler materials, which offer superior conductivity and thermal resistance. When it comes to silver welding machine price, it's essential to factor in the quality of joints they produce. Investing in a high-quality machine ensures precision and reliability, leading to strong and durable welds.

Exploring Laser Soldering Machine Features: Precision at Your Fingertips

Laser soldering machines stand as technological marvels, boasting an impressive array of features that cater to the diverse needs of soldering tasks. Each feature is a testament to the sophistication and innovation that defines these machines. Here, we delve into some of the key features that make laser soldering machines indispensable tools in various industries:

Adjustable Power Settings: Fine-Tuning Perfection

The ability to adjust power settings is akin to wielding a painter's brush with varying strokes of precision. Laser soldering machines with adjustable power settings grant users the power to calibrate energy output to match the intricacy of each soldering task. Delicate components call for a gentle touch, and this feature ensures that the right amount of energy is delivered without the risk of damage. For more robust applications, such as heavy-duty metal joints, a higher power output guarantees a firm, enduring bond. This feature doesn't just offer customization; it unveils a world of precision that translates into impeccable results.

Wavelength Options: A Spectrum of Possibilities

Laser soldering isn't a one-size-fits-all endeavor. Different materials have distinct interactions with light, and laser soldering machines address this with an array of wavelength options. These wavelengths correspond to specific materials, optimizing energy absorption and transfer efficiency. Whether you're working with metals, polymers, ceramics, or composites, the ability to select the appropriate wavelength ensures that every joint is perfected. This feature transforms laser soldering into a versatile art, where the right wavelength unlocks the potential of each material.

Precision Control: Crafting with Microscopic Finesse

The heart of laser soldering lies in its precision control. Imagine the accuracy of a surgeon's scalpel transferred to soldering joints. Laser soldering machines offer this level of precision control, enabling users to direct the laser with microscopic finesse. This precision is paramount in industries like microelectronics and jewelry making, where a single misstep can lead to costly errors. The precision control feature elevates laser soldering beyond a technique; it's an art that demands meticulous attention and rewards with flawless results.

Automated Processes: Efficiency Refined

In a world that thrives on efficiency, laser soldering machines with automated processes are the epitome of streamlined productivity. These machines take the guesswork out of soldering by automating intricate tasks. From alignment and positioning to power modulation, the machine's intelligence ensures that each soldering operation is executed flawlessly. Automation doesn't just save time; it guarantees consistency, even in the most complex projects. This feature empowers operators to focus on creativity and problem-solving, confident that the machine handles the technicalities.

Advantages of Investing in Silver Welding Machines: The Power of Silver

Silver welding machines are more than tools; they're gateways to a realm of advantages that redefine the quality and durability of your welds:

High Thermal Conductivity: A Heat Management Marvel

Silver, known for its exceptional thermal conductivity, transforms silver welding machines into heat management marvels. In high-heat applications, such as aerospace components and power electronics, the efficient dissipation of heat is crucial. Silver-based filler materials excel in this domain, ensuring that excessive heat doesn't compromise the integrity of the weld. The result? Joints that withstand temperature fluctuations and stress without faltering.

Reliability: Welds That Endure Time

When you invest in a silver welding machine, you're investing in welds that stand the test of time. Silver's inherent properties, combined with precise welding techniques, yield joints that don't merely connect; they endure. Industries that demand unwavering reliability, like medical devices and automotive manufacturing, turn to silver welding for joints that outlast challenges and years alike.

Low Electrical Resistance: The Efficiency of Flow

Efficient electrical flow is the backbone of many industries, from consumer electronics to industrial power distribution. Silver's low electrical resistance ensures that current flows smoothly, minimizing energy loss and heat generation. This makes silver welding an optimal choice for applications where resistance can't be tolerated. From intricate circuitry to high-capacity power transmission, silver welding machines optimize the flow of electricity, enhancing overall efficiency.

Incorporating these advantages into your projects isn't just a matter of welding; it's a strategic decision that elevates the quality, durability, and performance of your creations.

Conclusion

In the ever-evolving landscape of soldering and welding technology, laser soldering machines and silver welding machines stand out as pioneers of precision and durability. As you explore the world of laser soldering machine price and silver welding machines, remember to consider your specific needs and prioritize quality and reliability. By harnessing the power of laser technology and the robustness of silver-based welding, you'll elevate your welding projects to new heights of excellence.

Specifications:

| Specification | Value |

|---|---|

| Model No. | SLW-100/SLW-200 |

| Output Power | 100W / 200W - Based on requirement |

| Single Pulse Energy | 0-150 J |

| Machine Design Type | Desktop / Vertical |

| Laser Source | ND:YAG |

| Laser Wavelength | 1064 nm |

| Pump Lamp | Pulsed Xenon Lamp |

| Pulse Width | 0.1 - 20 ms adjustable |

| Pulse Repeated Frequency | 1 ~ 50 Hz adjustable |

| Welding Spot Diameter | 0.2 -1.3 mm adjustable |

| Observing System | Microscope / CCD - Based on requirement |

| Cooling System | Water Chiller |

| Power Supply | Single Phase AC 220V +10%, 50Hz/60 Hz, 4 KW |

| Running Environment | Temperature 5°C – 28°C Humidity 5% – 70% |

| Supported Application | Gold, Silver, Rose Gold, Copper, Platinum, Titanium, Argentine, Nickel, Aluminum, Stainless Steel etc. |