Wide Range Of Our Products

Ozone Laser Marking Machine For Metal

Know More

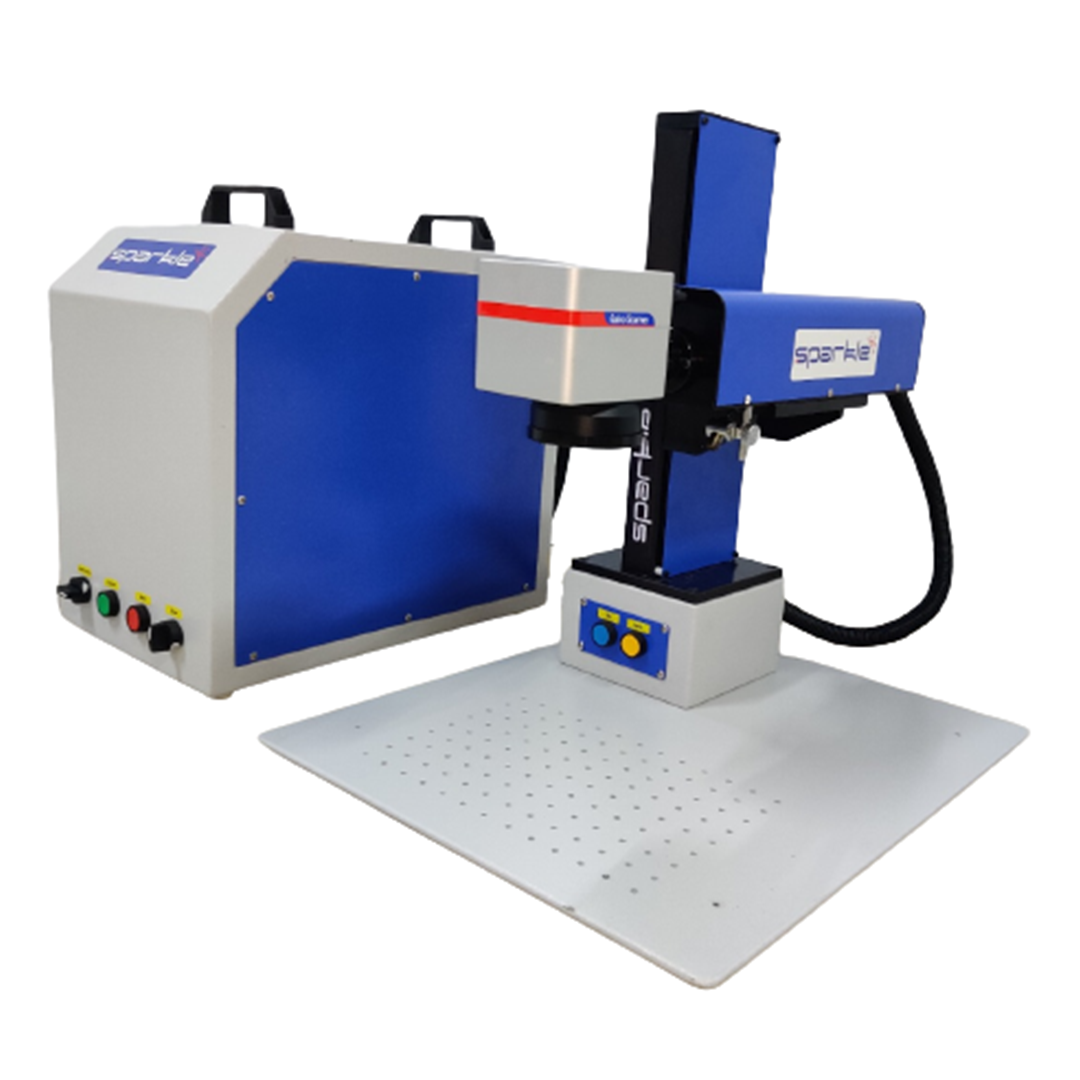

Opto Fiber Laser Marking Machine

Know More

Mega Laser Marking Machine

Know More

Rock Laser Marking Machine

Know More

Electro Laser Marking Machine

Know More

Rockside Laser Marking Machine

Know More

M360° Laser Marking Machine

Know More

Handy Compact Laser Marking Machine

Know More

Semi Flyer Laser Marking Machine

Know More

Auto Rotary Index Laser Marking Machine

Know More

Full Flyer Laser Marking Machine

Know More

Close Body Automation Laser Marking Machine

Know More

Convo Fly Laser Marking Machine

Know More

Mega Long Laser Marking Machine

Know MoreLaser Marking Machine

Welcome to our comprehensive collection of laser marking machines, a cutting-edge solution for precise and permanent laser marks across various materials. From industrial applications to small-scale businesses, these machines offer unparalleled efficiency, accuracy, and versatility. Discover the world of laser marking and discover how this technology can elevate your business to new heights!

Laser marking machines have brought about significant revolutionization in the world of product identification and traceability. With the ability to engrave, etch, or mark a wide range of materials with incredible precision, laser marking machines have become indispensable in industries spanning manufacturing, electronics, automotive, aerospace, and more.

In the realm of modern manufacturing and industry, precision, and efficiency are the keystones of success. Such versatile, high-precision laser marking machines by Sparkle Laser have transformed the way we engrave, etch, and mark a vast array of materials, offering an unparalleled level of accuracy and performance.

What sets laser marking apart from traditional marking methods, such as engraving or stamping, is its non-contact, non-invasive nature. The process involves using a highly focused laser beam to heat the surface of the material, causing it to change in appearance, texture, or color. This contactless approach eliminates the risk of damage to delicate or sensitive materials and ensures that the marked surface remains smooth and unaffected.

In the world of laser marking machines, it has varied applications, advantages, and the factors to consider when choosing the right one for your specific needs!

What are Laser Marking Machines?

Laser marking machine are nothing but innovative tools that make use of laser technology to create permanent laser marks on varied materials. Laser marking machines provide exceptional precision, resulting in clear, detailed, and high-quality marks as compared to other traditional marking machines. Such laser marking systems are best-known for delivering consistent and reliable results. It can be best used to give product labels, add serial numbers, barcodes, or engrave intricate designs on jewellery.

Applications of Laser Marking Machines

Laser marking machines find applications across diverse industries:- Product Identification and Traceability:

- Personalization and Customization:

Laser engraving allows for custom designs, logos, and personalization on items like jewelry, promotional products, and gifts.

- Medical Device Marking:

Laser marking on medical devices ensures compliance with regulations and enables precise identification of instruments and implants.

- Electronics and PCB Marking:

Electronics manufacturers use laser marking for labeling components, ensuring traceability and quality control.

- Automotive and Aerospace Part Marking:

Laser marking is vital for marking part numbers, barcodes, and serial numbers on automotive and aerospace components.

- Manufacturing and Automotive:

Laser marking is used for serial numbers, part identification, and branding on automotive components and electronics, enhancing traceability and quality control.

- Medical and Pharmaceutical:

In the medical industry, laser marking ensures the clear and permanent marking of medical devices, surgical instruments, and pharmaceutical packaging for safety and compliance.

- Electronics:

Laser marking is essential for PCB marking, chip identification, and branding of electronic components, facilitating product recognition and quality assurance.

- Aerospace:

In aerospace, laser marking is used for part serialization, traceability, and safety marking on aircraft components, contributing to aviation safety and compliance.

- Jewelry:

Laser marking allows for custom engraving, personalization, and branding on jewelry pieces, providing a unique and elegant finish.

- Packaging:

Laser marking is widely used for applying barcodes, QR codes, and batch coding on packaging materials, enabling efficient inventory management and product tracking.

In manufacturing, laser marking ensures products are easily identifiable, aiding in tracking and quality control.

Advantages of Laser Marking System

- High Precision and Accuracy:

- Non-Contact Marking:

Laser marking system is a non-invasive process that doesn't damage the material being marked, making it suitable for delicate items.

- Permanent and Durable:

Laser markings are resistant to wear, chemicals, and environmental factors, ensuring longevity.

- Versatility in Marking Materials:

Laser markers can handle various materials, from metals and plastics to ceramics and glass.

- Speed and Efficiency:

Laser marking is incredibly fast, allowing for high-throughput production in industrial settings.

Laser beams can create intricate designs with micron-level precision, ensuring clear and legible markings.

Choosing the Right Laser Marking Machine

- Material Compatibility:

Ensure that the laser marking system is compatible with the materials you intend to mark.

- Marking Speed and Depth:

Evaluate the required marking speed and depth for your application.

- Integration and Automation:

Consider whether the machine can integrate into your production line and support automation.

- Budget Considerations:

Determine your budget and explore options within your price range.

- Maintenance and Support:

Check for maintenance requirements and the availability of customer support and training.

Types of Laser Marking Machines

-

Laser Welding Machine:

The laser marking machines are ideal for intricating welding tasks across varied industries. You can flawlessly bond materials with advanced precision using our Laser Welding Machines.

-

CO2 Laser Cutting Machine:

The laser marking machines can achieve accurate and precise cuts with our CO2 laser cutting machines. They are highly versatile

-

Fiber Laser Welding Machine:

Experience high-speed, and precise welding using our Fiber laser welding machines. It is perfect for demanding industrial welding projects.

-

3D Die Laser Engraving Machine:

Scale your engraving projects with our top-rated 3D Die Laser Engraving Machines. Such laser marking machines are useful for adding intricate designs to huge surface areas.

How Laser Marking Machines Work?

Laser marking machines are simple and easy to operate. It works on the principle of focused laser beams interacting with the surface of the material. The laser beam's energy causes a localized reaction, which results in the discoloration or alteration of the material's surface, creating a permanent mark.

The laser beam is directed onto the material's surface. The absorption rates may vary for different materials and wavelengths thus, facilitating that the laser beam is absorbed effectively by the material.

The absorbed laser energy heats the material, causing a reaction such as vaporization, ablation, or color change. This reaction creates the desired mark on the material.

Modern laser marking machines offer high levels of precision and control, allowing users to define the shape, depth, and size of the marks accurately.